What is hyperspectral imaging?

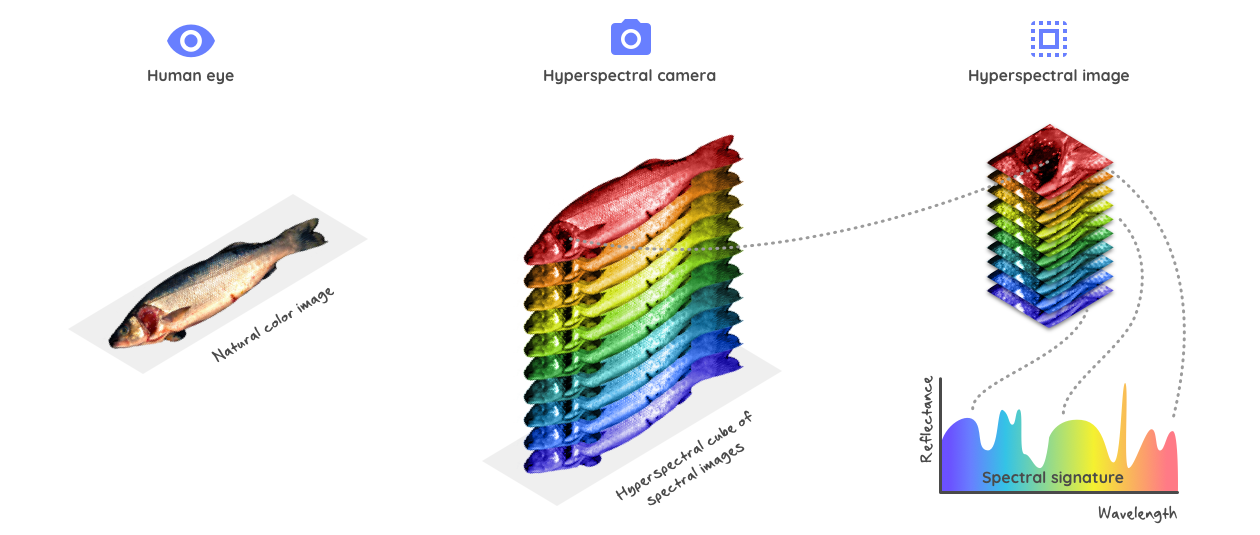

The human eye sees the world in three colors: red, green and blue (RGB). By mixing the amount of these three colors all other colors are created. A similar process is used for creating colors on television, computer screens, mobile phones and colour printing.

Cameras and color

A normal camera measures a picture also in red, green and blue. With a more special camera the colors can be broken down into many more colors and the intensity of the colors can be analyzed. A hyperspectral camera divides the three colors we see into many more bands and registers their intensity. This process of measuring electromagnetic wavelengths can be extended to parts of the spectrum that are invisible to the human eye such as Ultra Violet and Infrared.

Reveal information invisible for the human eye

The combination of detailed spectral analysis and the use of bands beyond the visible spectrum enables a hyperspectral imaging system to reveal information that cannot be captured with the human eye.

Hyperspectral food inspection

Hyperspectral food inspection makes use of hyperspectral imaging and has a number of advantages above classic inspection methods.

Non-destructive & 100% inspection

First of all imaging is non-destructive, non-contact and continuous. As such the inspected product has not lost any quality, there is no possibility for cross-contamination and 100% of the products can be inspected. Whereas other methods are often based on samples.

Product specific information

Secondly the analysis of the spectral fingerprint of substances can reveal information that normally cannot be captured by the human eye. A hyperspectral image can reveal the ripeness of a product beyond its colour only. The system can be installed in-line. The analysis is based on a Foodmodel© that is specific for each product. The outcome will for example trigger a sorting or grading action.